Complete Equipment For Oil Refining

The oil refining system consists of rendering kettle, decolorizer-dryer, deodorizer, soapstock kettle, crystallizer, filter machine, heat conduction boiler, vacuum system, refrigerating unit etc. The crude oil passed the process of degumming, deaeration, decolorizing, de-waxing, and deodorizing, to gain various of class oil.

The oil refining system consists of rendering kettle, decolorizer-dryer, deodorizer, soapstock kettle, crystallizer, filter machine, heat conduction boiler, vacuum system, refrigerating unit etc. The crude oil passed the process of degumming, deaeration, decolorizing, de-waxing, and deodorizing, to gain various of class oil.

There are three kinds of forms as follows: batch refining(below 50T/D), semi-continuous refining(20~80T/D), continuous refining(30T/D). Can be selected in accordance with request.

Our line of edible oil refining process systems are specially designed to produce an odorless, bland, and stable oil with the appropriate color for a wide variety of cooking and baking applications. From low-cost production of bulk commodity salad and cooking oils to development of the most sophisticated designer-type oils and fats system. We provide the oil expellers/oil press with the latest technology and lowest operation costs.

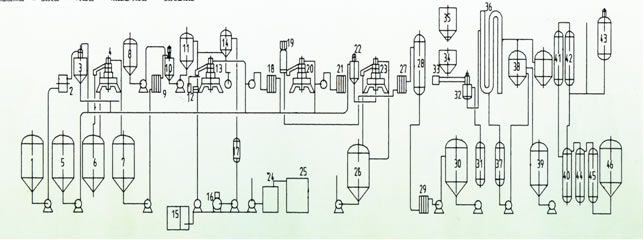

Process flow For Oil Refining

1 Batch Oil Refining

.jpg)

2 Continuous Oil Refining